The Tamarack Mine

Mine Overview

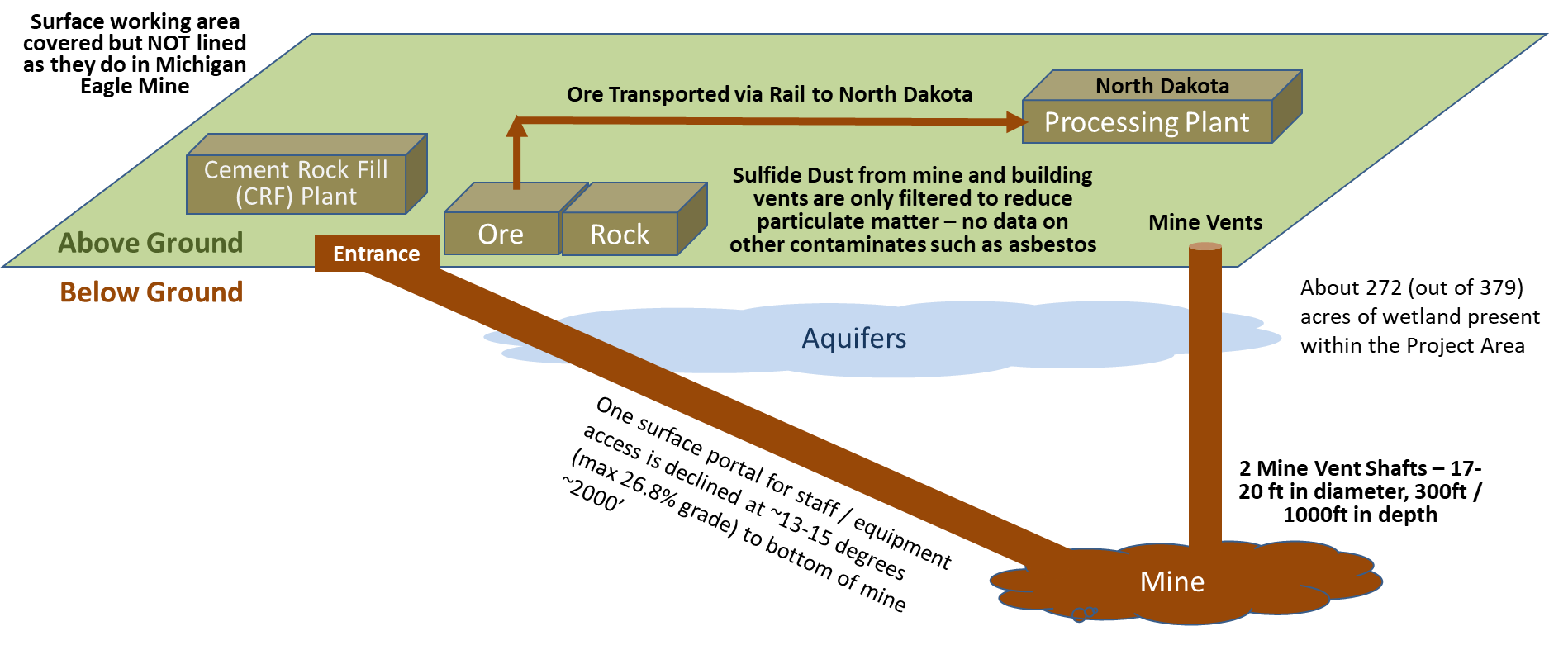

The proposed Talon Metals mine in Tamarack is an underground mine. Ore extracted from the mine is planned to be shipped to a new processing plant in North Dakota (announced by Talon in October 2022).

The mine will have one surface portal to provide primary access for personnel, materials and ventilation plus 2 vent shafts approximately 17-20 feet in diameter at different depths. The surface portal will decline at a slope of approximately 13-15 degrees and will be approximately 2000 feet deep reaching to the bottom of the mine with a 12" concrete liner. Since this is a very wet mine, this steep ramp will be very slipperly and dangerous as machinery is driven in and out of the mine.

Once down to the level of the deposit, lateral tunnels are created around and into the mineral deposits to extract the ore.

Stopes (large underground rooms) are created through blasting (mulitple times a day) and the ore is then brought to the surface for storage and shipping. It is expected that the mine will extract

approximately 3,600 metric tonnes of material per day. This is about 4000 US tons per day. At approximately 100 tons per rail car, this equates to about 40 rail cars per day.

Dust and Blasting Concerns

Underground blasting will be used to release ore from bedrock. We note that at the Eagle Mine in Michigan, people can feel the blasts at all hours often twice a day from MANY miles away. Dust created by the blasting underground is vented to the surface where it is must be filtered for fine toxic materials (which Talon does not plan to do). Mine operations generate significant air borne pollution vented directly into the atmosphere and as such, Talon needs to filter the main exhaust shafts with industrial air filters capable of removing potentially toxic dust from blasting.

There would be over 6000 blasts over the life of the mine - high potential of causing building damage as the surface is all sand. Underground blasting creates toxic SO2, H2S and NOx gases vented into the air. These gases are toxic and when combined with air and moisture will create acid rain. These gases can propagate 100's of miles when vented.

Blasts can open cracks in the bedrock and grout, increasing water quantities that must be pumped. The shallowest planned ore mining is located about 300 feet below surface.

Talon now plans to "enclose" in buildings most operations related areas and ore storage facilities. But floors may be just gravel (said to be "impervious" by Talon). However, gravel is NOT impervious to water flow and even asphalt will crack and leak over the life of the mine. Flooding, roof leaks and water usage for dust management will contaminate the soil under the buildings.

At the Eagle Mine in Michigan, the TDRSA (Temporary Development Rock Storage Area) is lined with both a primary and secondary lining. Lining surface areas is a best in class technique and originally, Talon said that they will be "better" than the Eagle Mine. They have since proven that statement wrong.

We note that rail cars must have seep holes at the bottom to drain water that may collect in the car. These seep holes will also leak toxic materials all along the railways from Tamarack to North Dakota. In addition, the ore loaded into the train cars will likely be very wet given the amount of mine water that must be pumped out. In cold weather, this ore will freeze in the rail car by the time it gets to North Dakota making it impossible to remove for processing. How will Talon deal with this in an environmentally safe way?Originally, an on site processing plant was planned to process the extracted ore. This plant would have produced a significant quantity of high sulfide tailings. The original plan was to backfill the fully mined stopes (the large underground caverns left by removing the ore) using a cement based paste backfill mixed with high sulfide tailings and development waste rock. They now plan to use development rock and imported sand and gravel, mixed with cement, to fill these areas. However, the developmnet rock will need to be crushed potentially creating more toxic high sulfide dust and this mixture is not impervious to water leakage, increasing the potential for more mine contact water that must be pumped out.

Water Concerns

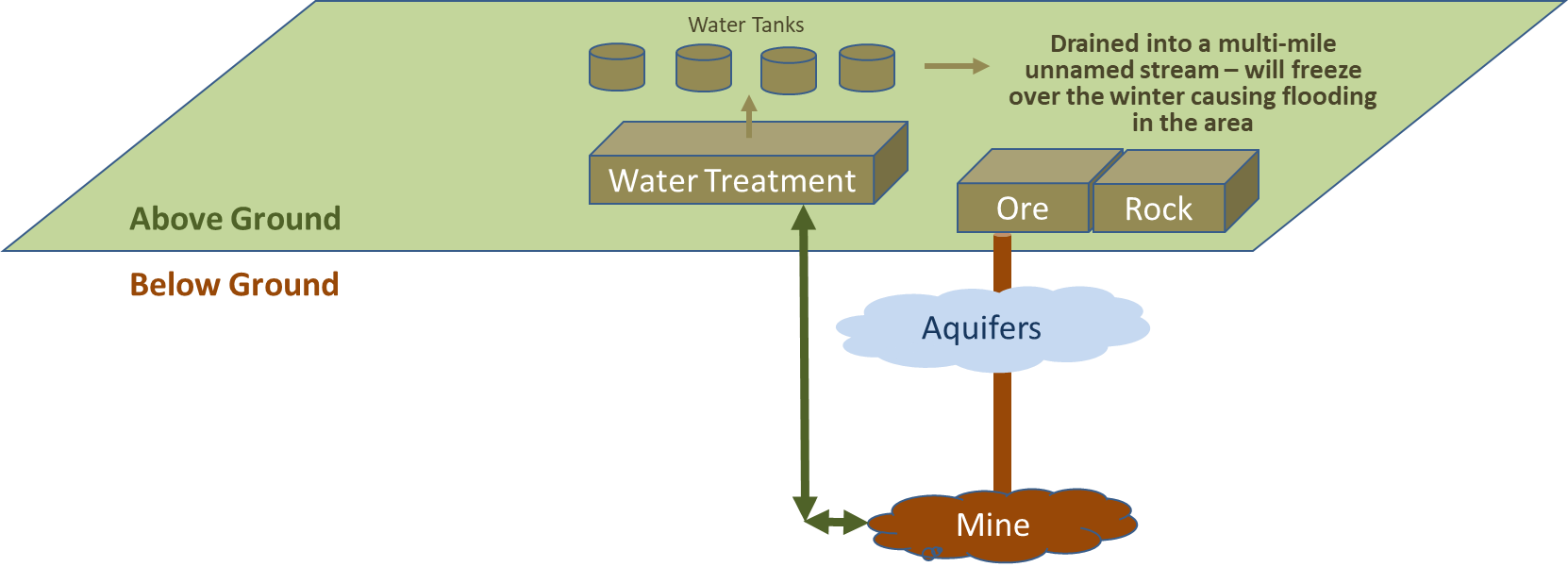

There are two main sources of water that must be removed from the mine, service water needed for underground operations and mine water entering from all of the aquifers above via what Talon calls "water bearing features" in the exposed rock.

Relative to mine service water, the Eagle Mine report and tour information, the 2020 Talon PEA and the 2021 PEA all talk about how much water is needed for underground operations. You need to pump water down into the mine for:

- Diamond drill lubrication for pilot hole drilling and flushing of waste

- Pressure washers to clean the underground equipment

- Dust suppression for the underground crusher and conveyor loading area

- Pressure washers for general dust mitigation

- Shotcrete machine cleaning and sump flushing

- Backfill Line flushing

- Removal of loose rock after blasting

- Muck pile wash down

- And other purposes

Generally, based on the Eagle mine service water reports in 2024, between 50,000 to 116,000 gallons per day will need to be pumped down into the mine. This water does not soak into rock, it needs to be pumped out, thus dewatering of the mine is required and becomes a part of the total mine pumping requirements.

In addition, both the 2020 and 2021 PEA conclude that there will 9.9 gallons / minute per water bearing feature coming in from the aquifer with an average of one water bearing feature per 216 meters of drill data as measured through past data logging. It is not clear that this is scientifically supportable level of water inflow based on Talon facts and of course, this inflow increases as the mine surface area increases. The model used by Talon may not apply in this area as there are no underground mines in Minnesota. The amount of dewatering may be much higher than the Talon estimates of between 2.3-2.6 million gallons of water per day. However, given the stopes are not impervious to water leakage, one could expect the number of water bearing features to increase dramatically. In addition, daily blasts are likely to open new fissures in the bedrock increasing the water flow. This raises the question, How much beyond the 2.3 million gallons a day must now be pumped? Will it be 5 million gallons? More?.

Inevitably, Talon must ship in gravel and sand to be used for filling the stopes as the development rock is used up. Talon plans to extract 3600 tonnes (metric) of material per day (per their PEA). That's about 4000 US tons. To replace that material, logically, you would need to fill with approximately 4000 tons per day of gravel (mixed with a bit of cement for the paste fill). Now it is true that sand and gravel can take up more area per tonne of weight due to the air gaps between the grains of sand and gravel. But loosely backed sand and gravel cannot be used since water will leak through these air gaps greatly increasing pumping requirements. The sand and gravel, mixed wth cement must be highly compacted to be as "water resistant" as possible so that indeed, close to 4000 tons per day may be needed (despite what Talon claims). Once development rock is exhaused, that's another 40 large train cars of sand and gravel per day that must be shipped into the facility from someplace, everyday, 365 days a year for many years. It is not clear where they might get this material.

The 2.3+ million gallons of water is dirty water (contaminated by sulfide dust as well as direct contact with the sulfide ore). Treatment of this water would require large, energy intensive industrial filters that change the water chemistry impacting local lakes, wetlands and aquifers when the water is released into the environment. In addition, how does Talon know how to engineer the size of this treatment plant when they appear to have no accurate method to determine how much added water will result from blasting and leakage from filled stopes? Will they just dump contaminated water that they can't filter? Talon currently plans to dump this water in an unnamed stream which eventually flows into Big Sandy Lake. However, this small stream will freeze during the winter causing the water to flood local areas. And there is no information on the impact to lake, well and wetland surface water levels. Can the aquifers be replenished? All unanswered questions.

The Michigan Eagle Mine is an underground nickel-copper mine similar to what is being proposed for Tamarack. Consider the document: www.eaglemine.com/_files/ugd/c6167e_ffef87e367c44b98a35291842533f161.pdf. This Eagle Mine Anomalies Report listed over 20 monitoring situations that show levels of pollution and water chemistry changes outside the planned benchmark range. For example, QAL023B monitoring point showed the water level was 5.6 feet below the calculated minimum baseline level. Mine attributed this drop in water levels to two main sources; pumping of the mine services well and groundwater infiltration into the mine. This drop in water levels is then due to an average pumping requirement of 80,000 to 120,000 gallons a day (from 2024) from the mine and service wells. If 5.6' drop is seen at these pumping rates, what happens when Talon estimates over 2,300,000 gallons pumped per day in Tamarack? How will this impact well water levels, lake levels and wetlands?

In addition, the Eagle mine listed at least 20 monitoring events that show levels of pollution and water chemistry changes outside the planned benchmark range - some with sulfate levels that exceed Minnesota's wild rice standards by a factor of 1500.

Rock and Ore Storage Concerns

There will likely be multiple storage facilities on site at the mine. Development rock excavated from the tunnels that descend into the mine and connect the various mineral deposits will generally be stored on the surface. This rock can be used later to fill mined out stopes to some extent but must be crushed (causing more toxic dust) since this rock may be contaminated with sulfide and other toxic minerals. The Eagle Mine report (referenced above) lists 33 toxic substances being monitored. In addition, ore must be stored prior to transport to North Dakota. These storage areas must be lined to prevent contamination from seeping into the ground water. We note that Eagle Mine TDRSA (Temporary Development Rock Storage Area) is lined with both a primary and secondary lining. A leak detection system is installed between the liners to monitor primary lining integrity. A total of approximately 65 gallons of water was purged from the leak detection sump in 2024 with sulfate levels up to 1300 PPM, a larger volume than earlier years. Note that the Minnesota wild rice standard is 10 PPM for sulfates. Thus we see that the lining system does leak after only a few years of operation. The leak levels are currently very small at this point but as noted in the 2020 Eagle Mine report, increasing slightly over time. However, Talon has no plans to use liners.